(Armorcast Sheath Repair and Structural Strengthening Material)

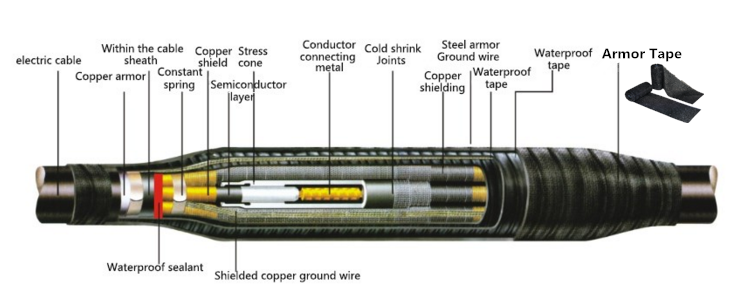

Unique-Technology Cable Armorcast is a flexible fiberglass knit fabric strip, saturated with a curable polyurethane resin syrup that starts to cure after adding water. Once wetted, the fiber strip becomes tacky and sticks to itself, so it wraps easily around almost any shape or size.It’s applied to reinforth shield and connector of cable.Mostly use in aerial, buried and manhole applications and is Ideal for strengthening old cables, splices and auxiliary seals.

It resists moisture, acids, alkalis, ozone, gasoline and high temperatures.

Features

1.Using wet type of rubber with high resistance to sunlight as the backing material net cloth backing, easy to use, wrap on the cable accessories or electric cable directly outside protective layer to form a high strength, can strengthen the mechanical protection of connectors and cables.

2.Once wet, the fiber strip becomes tacky and sticks to itself

3.Compatible with coaxial, copper, fiber cables, polyethylene or lead-sheathed cable, pressurized and non-pressurized cable

4.Ideal for strengthening old cables, splices and auxiliary seals

5.Fast and easy to apply, yet hardens to a strong and maintenance-free coating

6.Resists moisture, acids, alkalis, ozone, gasoline and high temperatures.

7.Can be used on pressurized or nonpressurized cable and on either polyethylene or leadsheathed cable

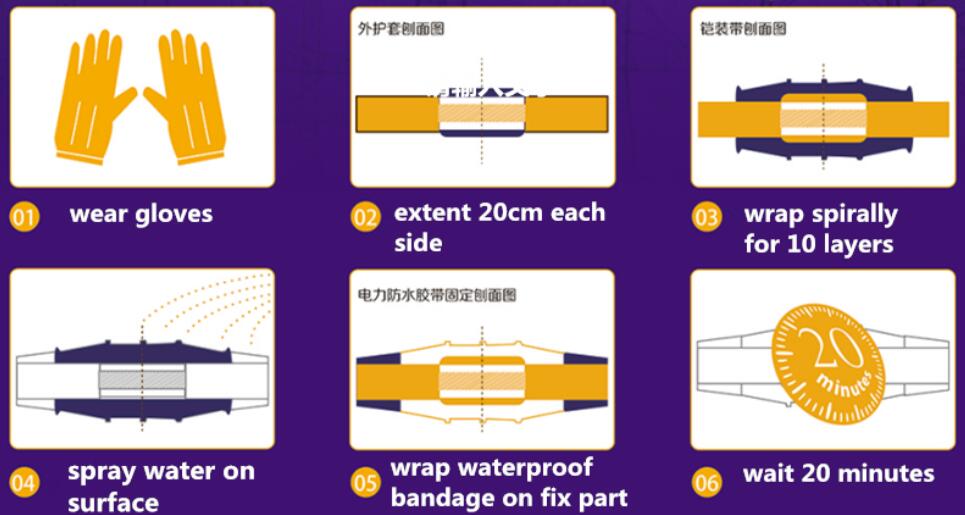

1. Prepare the surface by cleaning and roughening the cable.

2. Put on enclosed latex gloves.

3. Open foil pouch and immerse bandage in temperate fresh water for 10 seconds.

The entire contents must be used once the package is opened.

4. Apply around the cable extending up to 50mm either side of the cable to ensure complete coverage.It is important that the bandage is applied.

5. Quickly as curing begins once it is taken out of the water.

6. Whilst wrapping, pull each layer tightly by using your hand to mould and squeeze the layers together.

Continue this action during and upon completion.